Protoblast has been building dust collectors for the abrasive blasting industry for over 40 years and have developed one of the most hardy, robust dust collectors without compromising the efficiency and ease of regular maintenance.

Introducing The Horizontal Cartridge Dust Collector

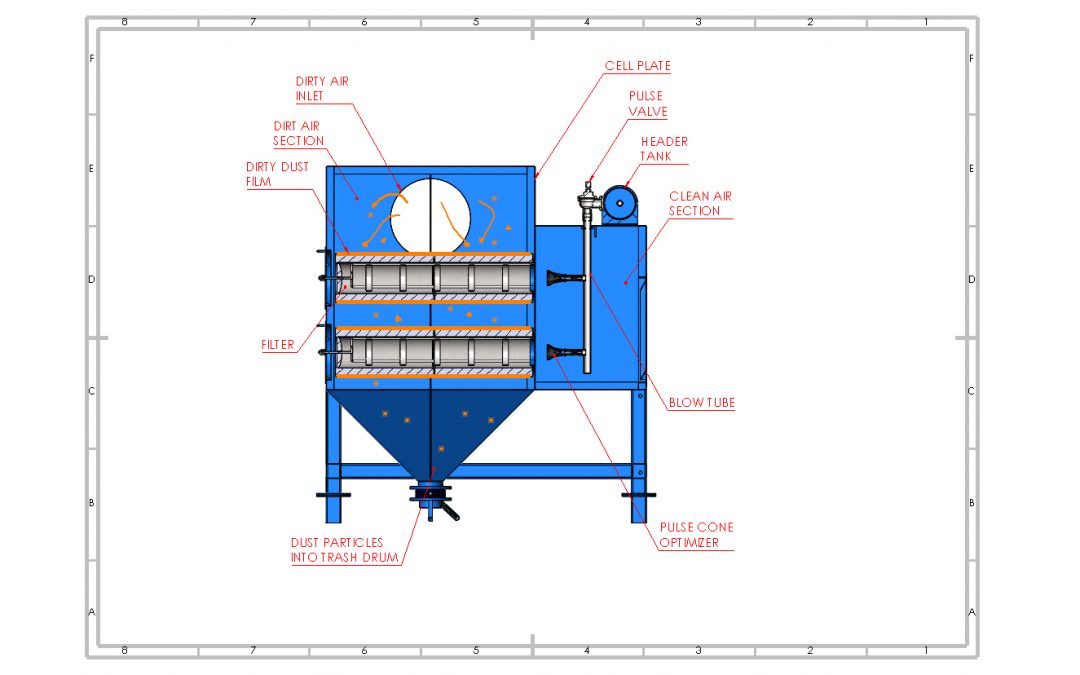

The Horizontal Cartridge Dust Collector was developed to overcome the issue of having to enter the dust collector body to change the filters. Many options were evaluated but the final decision was a dust collector with the filter cartridges positioned horizontally supported by a frame on which the filter slides.

What Are the Advantages?

- A big advantage with this style is that the dirty air is drawn in above the filters where the velocity is decreased and then the flow is downward between the filter shrouds. The advantage is that, when the filters are pulsed, the dust is encourged to fall down into the hoppers. This provides an increase in the pulse effectiveness which in turn increases the filter life.

- Filtration is through high efficiency cartridge type filters. These filters have a filtration efficiency of MERV 10 as per ASHRAE 52.2-2007. In simple terms all particles above 1.0µm will be filtered when new.

- Protoblast uses an intelligent Pulse Controller which measures the resistance that the cartridges are producing and only pulses when it is needed. This saves on compressed air consumption which in turn saves money. The controller can be run with options such as Broken Bag Detectors, real time monitoring from a remote source and also air quality monitors which is a sensor that can be installed in close proximity to the dust collector which monitors the air and the condition of the atmosphere. This is logged and can be monitored from a remote PC and recorded in the case that there is any issues.

- The dust discharge comes standard with 6” (150mm) butterfly valves which feed into 200L drums. The other options are a rotary valve discharge or pneumatic slide gate valve and can be designed to support bulkbags or custom bins.

- The fans that Protoblast use are built to suit the individual volume and static pressure requirements. They are Centrifugal Backward Inclined fans with the impellor mounted directly to the motor shaft. They are impossible to overload and require very little maintenance as there are no extra bearings or belt drives. We highly recommend a VSD is used to drive the motor as the power saving from this is very substantial and it provides great protection for the motor.

An Important Consideration

A very important point to consider when designing a dust collector is the air to cloth ratio, or in other words the velocity at which the air will be passing through the filter media. Our standard ratio is 1:212 which has proven to be efficient in the abrasive blasting industry. We have often supplied dust collectors to be used on blast chambers that also get used for hot metal spraying. If this is the case, we increase the ratio as the dust from this process is very sharp and damages the filter media if flowing at a high velocity.

In conclusion when considering a dust collector for your Abrasive Blasting facility, the Protoblast solution should be your preferred choice as it will save you money each and every day of operation. We take pride in producing equipment that wil provide the best return on investment possible.

Contact Us

If you have questions please do not hesitate to contact Protoblast on 02 4677 2320, contact us online or email us at sales@protoblast.com.au